versatile shipping carton fabricator how do innovative cardboard box manufacturers drive sustainable packaging efforts?

Investigate the captivating universe of corrugated packaging creation via this thorough tutorial. This will investigate the fundamental stages of forming simple stock into tough containers that defend products through distribution. Including corrugation, printing, and assembly, we illustrate the complexities of this indispensable industry.

- Learn about the various forms of corrugated cartons and their unique uses.

- Examine contemporary progressions in carton manufacturing.

- Gain insight into the ecological footprint and sustainable alternatives.

Whether a pupil, technician, or industry aficionado, this manual offers useful insights into the ever-evolving corrugated carton market.

Formulating Answers via Corrugated Fiberboard

Corrugated cardboard, often overlooked as a simple packing material, is truly a versatile medium for crafting. Its resilient traits permit the crafting of original constructs and layouts, embracing efficient compartments to imaginative decorations. With cleverness, one can shape this conventional material into something extraordinary.

List the endless possibilities of corrugated cardboard crafting by:

- Trying various methods such as slicing, bending, and stacking

- Incorporating reused elements for an environmentally responsible process

- Presenting your projects to stimulate others

Due to its inexpensive quality, access, and flexibility, corrugated packaging board attracts creators of all age brackets and skills. Harness your inventive talent and facilitate your imagination to grow through this modest element.

The Fusion of Engineering and Aesthetics in Corrugated Boxes

Corrugated container design combines a compelling fusion of engineering and design sensibility. It's not simply about constructing a box; it's about crafting a protective vessel that preserves goods throughout shipment while also making a memorable statement to buyers.

An experienced maker identifies the sophisticated qualities of corrugated carton board, adjusting its dimension, flute design, and layout to address distinct specifications of each unit.

- Also, stylistic aspects matter greatly.

- A skillfully constructed carton appears promptly noticeable on racks, drawing attention from prospective customers.

- Essentially, box creation merges preservation and visual appeal.

Meeting Demand: Scaling Your Corrugated Box Production

As enterprise prospers and demands climb, it's necessary to assure resources for meeting purchaser wants. Scaling your corrugated box production can be the key to keeping operations running smoothly and maintaining a strong reputation for reliability.

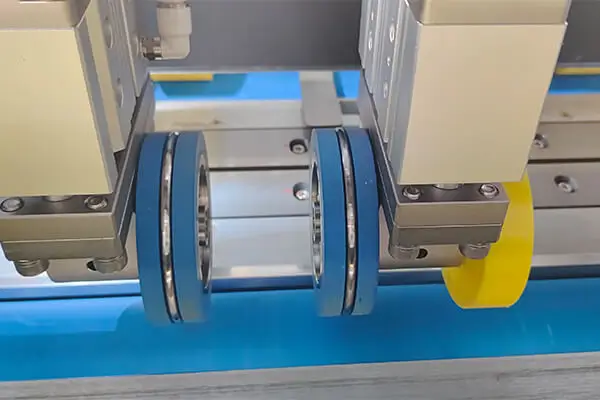

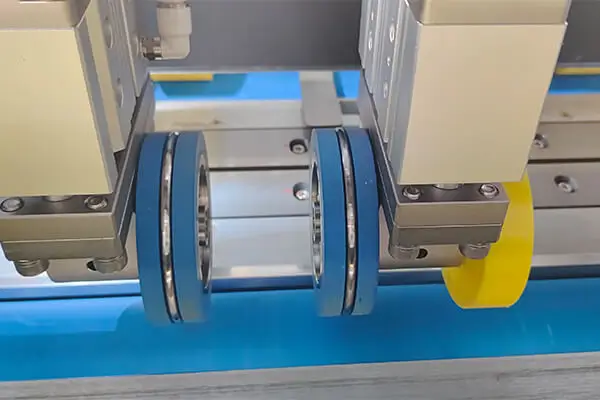

Primarily, analyze your production processes. Survey deployed equipment and crew to recognize likely slowdowns or areas for development. Later, evaluate means to improve production size. Assess procuring latest devices or upgrading current hardware to augment throughput.

Remember, it's not just about producing more boxes; it's about efficiency of your entire production process. Apply efficient production techniques to reduce scrap and optimize asset usage. Refine operations, computerize monotonous duties, and focus on staff development to form a productive group.

In conclusion, cultivate dependable connections with providers to guarantee continuous resource delivery. Using these methods, you can efficiently boost container fabrication and fulfill rising buyer requests.

Revolution in Corrugated Design

The carton business continuously expands, encouraged by urges for sustainable, effective, and imaginative techniques. Corrugated pulpboard, a steadfast product for years, experiences renewal driven by inventive progressions. From durable builds to intelligent functions, corrugated boards welcome modern innovations. Manufacturers are exploring new ways to enhance the performance of corrugated packaging, incorporating eco-friendly materials and processes. The impact is a tide of original packaging proposals changing the commercial terrain.

These developments tackle major obstacles confronting enterprises, including minimizing refuse and streamlining distribution. Patrons correspondingly profit from these improvements, acquiring cartons that are firmer and more user-centric. The prospect for corrugation is optimistic, brimming with opportunities for eco-friendly and streamlined packaging solutions.

Eco-Conscious Corrugated Packaging: Sustainable Selections

Corrugated packages act as a core feature of today’s fulfillment processes. Frequently developed from board, such containers exert significant pressure on natural world. But, there's growing awareness about the need for sustainable practices, and this extends to the production of corrugated boxes. Luckily, there are innovative solutions available to make these containers more eco-friendly.

An essential characteristic includes employing repurposed board. Through employing manufacturing or consumer leftovers, the need for fresh resources decreases, preserving woodlands and natural assets.

Furthermore, manufacturers are investing in sustainable production processes. This strategy incorporates maximizing power savings and decreasing surplus throughout operations. Shoppers can participate by picking containers endorsed as earth-friendly. Check for marks such as FSC or SFI that confirm accountable sourcing and fabrication.

Through adopting these methods, we guarantee cartons continue as essential economic components while reducing ecological impact.

Upholding Standards in Container Manufacturing

Achieving peak performance in corrugated box production hinges on meticulous quality control measures. Opening with raw material selection and closing with product scrutiny, each action requires steady attention. Stringent protocols are implemented throughout the manufacturing process to guarantee that each box meets the highest specifications.

- Checking base materials for faults, robustness, and sameness is necessary to precluding ensuing complications.

- Maintaining exact measurements and allowances in shaping and bending guarantees cartons are mechanically stable and suitable for purpose.

- Consistent evaluation of design application maintains bright imagery and readable letters

- Utilizing machine-driven monitoring solutions enhances workflow and exactness in inspection tasks

Through committing to quality evaluation across processes, makers deliver shipments that are tough and appealing. Such pursuit of quality gratifies client expectations and improves market presence.

Container Printing: Marketing and Impression

Carton image printing acts as an important feature of brand exposure. When customers observe your articles, the box functions as a vital channel for expressing brand identity. A thoughtfully developed image on a container can draw focus, represent brand character, and promote purchase behavior.

Furthermore, corrugated box printing offers a range of options to customize your packaging. Utilizing dazzling colors to novel symbols, it is feasible to communicate brand traits via packaging shape.

Ultimately, packaging branding is beyond necessity – it operates as an influential means to strengthen brand awareness and engage your audience.

From Base Components to Final Goods: The Corrugated Carton Process

The construction of packaging is a remarkable process changing basic ingredients into a vital delivery and containerization method. It all begins with the procurement of pulp, typically derived from recycled sources. Then, pulp is formed into sheets of corrugated sheet, having a fluted core trapped between two flat liners.

These boards are rigorously cut to exact specifications, then bonded with dedicated equipment to fabricate the desired packaging design. Adhesives play a crucial role in sealing the components together, ensuring a strong and durable structure.

Ultimately, cartons pass strict inspection procedures to ensure mechanical strength and compliance with sector norms.

Beginning from basic sources, the container evolves into a flexible packaging innovation, equipped to defend numerous products in transit.

Worldwide Carton Industry: Patterns and Prospects

The worldwide container sector encounters a period of expansion. This lively industry is motivated by expanding client needs for shipment. Central corrugated box maker motivators encompass rise of internet sales and requirement for sustainable parcels