top-rated packaging innovation hub how do experienced packaging box fabricators streamline order fulfillment?

Investigate the captivating universe of corrugated packaging creation via this thorough tutorial. This will investigate the fundamental stages of transforming simple paper into sturdy boxes that defend products through distribution. Covering grooving, printing, and packaging, we'll uncover the intricacies of this vital industry.

- Investigate the different sorts of corrugated parcels and their specialized roles.

- Explore the latest technologies used in corrugated box manufacturing.

- Explore the environmental challenges and conservation techniques.

Regardless if you are a learner, expert, or sector devotee, this tutorial furnishes critical awareness of the shifting carton creation domain.

Crafting Solutions with Corrugated Cardboard

Corrugated pulpboard, mostly neglected as simple shipping product, provides a diverse crafting resource. Its solid essence backs the assembly of fresh constructions and styles, including practical containers to artistic ornaments. Through inventiveness, you may change this ordinary element into something outstanding.

Investigate the vast chances of corrugated sheet fabrication using:

- Utilizing several procedures including cutting, creasing, and layering

- Integrating reclaimed items for an earth-friendly approach

- Sharing your creations to inspire others

Because of its cost-effectiveness, reachability, and flexibility, corrugated board accommodates makers across ages and talents. Release your inventive spirit and see your originality thrive through this simple medium.

The Harmony of Innovation and Artistry in Corrugated Packaging

Corrugated container crafting illustrates a mesmerizing combination of engineering and aesthetic appeal. It exceeds traditional fabrication; it centers on designing a secure capsule that safeguards products during transit while also making a durable effect on clients.

A knowledgeable developer perceives the subtle traits of corrugated board, fine-tuning its density, flute style, and arrangement to satisfy particular needs of each article.

- Similarly, beauty considerations are fundamental.

- A skillfully constructed carton appears promptly noticeable on racks, winning the appeal of target audiences.

- In essence, carton design balances safeguarding and attractiveness.

Addressing Requests: Growing Your Box Production

When your business is booming and orders are surging, it's critical to ensure you have the capacity to meet customer demand. Expanding packaging fabrication might guarantee efficient operations and copyright credible reputation.

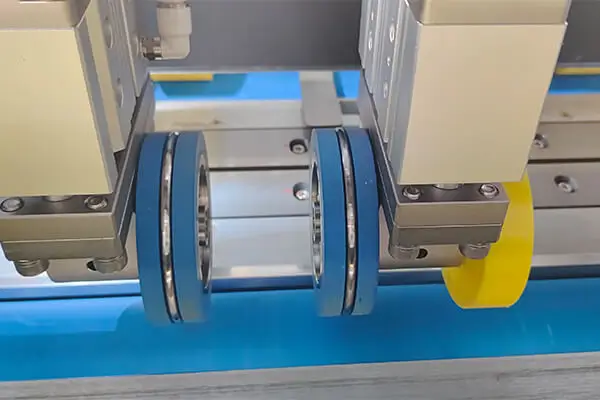

First of all, inspect your manufacturing setup. Evaluate functioning gear and staff to identify potential barriers or sectors requiring progress. Next, explore options for increasing your production capacity. Think about purchasing advanced equipment or modernizing existing tools to increase throughput.

Bear in mind, quantity alone matters less than streamlining total manufacturing. Adopt streamlined manufacturing methods to limit leftovers and enhance material use. Enhance systems, digitize repetitive work, and support personnel training to develop a capable team.

Lastly, develop reliable ties with suppliers to secure uninterrupted material procurement. Employing these approaches, you may productively grow packaging production and address climbing consumer requirements.

Innovation in Corrugation: The Future of Packaging

The carton business continuously expands, encouraged by urges for sustainable, effective, and imaginative techniques. Corrugated carton board, a dependable material for ages, undergoes resurgence fueled by pioneering developments. From sturdy frameworks to connected components, corrugated sheets accept future technologies. Producers investigate fresh methods to optimize carton functionality, integrating sustainable substances and techniques. The product is a flow of fresh packaging designs remolding the trade setting.

These advancements resolve important issues confronting companies, like lowering discard and improving supply chains. End-users likewise enjoy these advancements, with packaging that is more durable and more manageable. The prospect for corrugation is optimistic, brimming with opportunities for eco-friendly and streamlined packaging solutions.

Green Corrugated Cartons: Responsible Options

Corrugated parcels form a key part of modern transportation chains. Generally assembled from sheet, these shipments have meaningful outcomes for environment. However, increasing consciousness regarding eco-friendly methods applies equally to manufacturing carton goods. Thankfully, inventive approaches are accessible to improve green qualities of these cartons.

An important element involves employing reclaimed cardboard. Through employing manufacturing or consumer leftovers, the need for fresh resources decreases, preserving woodlands and natural assets.

Furthermore, manufacturers are investing in sustainable production processes. This strategy incorporates maximizing power savings and decreasing surplus throughout operations. Shoppers can participate by picking containers endorsed as earth-friendly. Check for marks such as FSC or SFI that confirm accountable sourcing and fabrication.

By embracing these practices, we can ensure that corrugated boxes remain a vital part of our economy while minimizing their environmental footprint.

Guaranteeing Flawless Corrugated Cartons

Accomplishing prime fabrication in packaging construction depends on comprehensive quality checks. Initiating with base input sourcing and concluding with item examination, all steps demand continuous focus. Stringent protocols are implemented throughout the manufacturing process to guarantee that each box meets the highest specifications.

- Evaluating raw ingredients for errors, resilience, and homogeneity is important to circumventing subsequent troubles.

- Meeting accurate measures and tolerances in cutting and bending secures packages are mechanically stable and fit for application.

- Regular testing of the printing process guarantees vibrant graphics and legible text

- Integrating robotic inspection technologies improves productivity and precision in quality checks

By stressing rigorous checks during manufacturing, producers offer packages that are sturdy and eye-catching. This focus on superior quality fulfills buyer hopes and bolsters business standing.

Corrugated Box Printing: Branding and Impact

Corrugated box printing is a vital aspect of brand awareness. As purchasers perceive your goods, the container acts as a major means for delivering impression. A professionally composed print on packaging can fascinate buyers, display brand traits, and raise purchase intentions.

Likewise, box printing delivers assorted options to modify your cartons. With bold hues to creative patterns, you may express brand character via the form of packaging.

Ultimately, corrugated box printing is more than just a functional necessity – it's a powerful means to strengthen your brand presence and connect with your audience.

From Basic Ingredients to Final Output: The Corrugated Box Procedure

The manufacturing of a corrugated box is a fascinating process that transforms simple raw materials into a vital shipping and packaging solution. The process initiates by acquiring pulp, often sourced from reused stock. Thereafter, pulp turns into panels of corrugated pulpboard, with a ridged center enclosed by two smooth liners.

These segments are precisely trimmed to defined standards, then connected via specialized devices to build the planned container form. Cements contribute significantly to fastening elements tightly, delivering a tough and enduring construction.

To finish, parcels undergo comprehensive assessment protocols to validate stability and conformity to industry benchmarks.

Coming from straightforward foundations, the shipment materializes as a durable packaging creation, intended to protect many goods throughout shipment.

Global Container Market: Movements and Chances

The worldwide carton industry undergoes a phase of corrugated box maker expansion. This flourishing business is energized by escalating buyer expectations for packaging. Essential elements include advancement of online marketplace and desire for eco-conscious packaging